Driving EBITDA Growth by Improving Performance within the Traffic Management Services Sector

We partnered with a prominent traffic management services provider to transform its processes and embed a culture of continuous improvement, resulting in a turnaround in profitability.

Key impacts:

More than £1 million impact in annualised benefits

Projected 16% profitability increase

Teams fully engaged, trained in and leading operating processes effectively

The challenge: Improve operational performance to enable EBITDA growth

Our client, a prominent traffic management services provider operating in England and Wales, was undergoing a significant transformation. Following a merger and comprehensive rebranding, the company’s core strategic objective was to significantly increase revenue and grow EBITDA by driving operational efficiencies across its regions.

One of the key underperforming regions was identified to target performance improvements through a change in culture. A lack of standardised processes and performance benchmarking had created a gap in operational effectiveness, leading to inefficiencies that meant costs were outpacing revenue.

We partnered with the client to identify the root causes and develop a comprehensive transformation plan that would improve regional performance and eliminate wasteful practices, enabling the business to exceed revenue and profitability targets.

The solution: Embed a culture in which people and processes drive success

We deployed an integrated approach to address the client’s challenges, focusing on the key areas of People, Performance and Digital capabilities.

During an initial analysis phase, we conducted a systematic assessment of the business with the primary goal being to identify the underlying issues resulting in poor performance.

Our approach in this phase centred on:

Data-driven analysis: We carried out in-depth analysis to understand the operational dynamics and highlight where variations in performance were occurring.

Performance impacts: We identified clear cause & effect relationships between financial performance, operational performance, operating systems, key business processes, leadership behaviours and overall team environment.

This enabled us to focus on developing and implementing targeted changes that would deliver the greatest improvements.

The implementation: Targeted changes to transform operational effectiveness

Based on initial analysis findings, the delivery phase focused upon systematic implementation of major improvement initiatives:

Collaboration and standardisation: Through an Integrated Project Team, we worked with central and regional teams to develop best practices and a standardised approach that targeted the underperforming region, with further planned roll out and cascade organisation wide.

Operational excellence: Tools, processes and standards were redefined and implemented with respective teams to ensure sustainable impact and alignment with the company’s performance objectives.

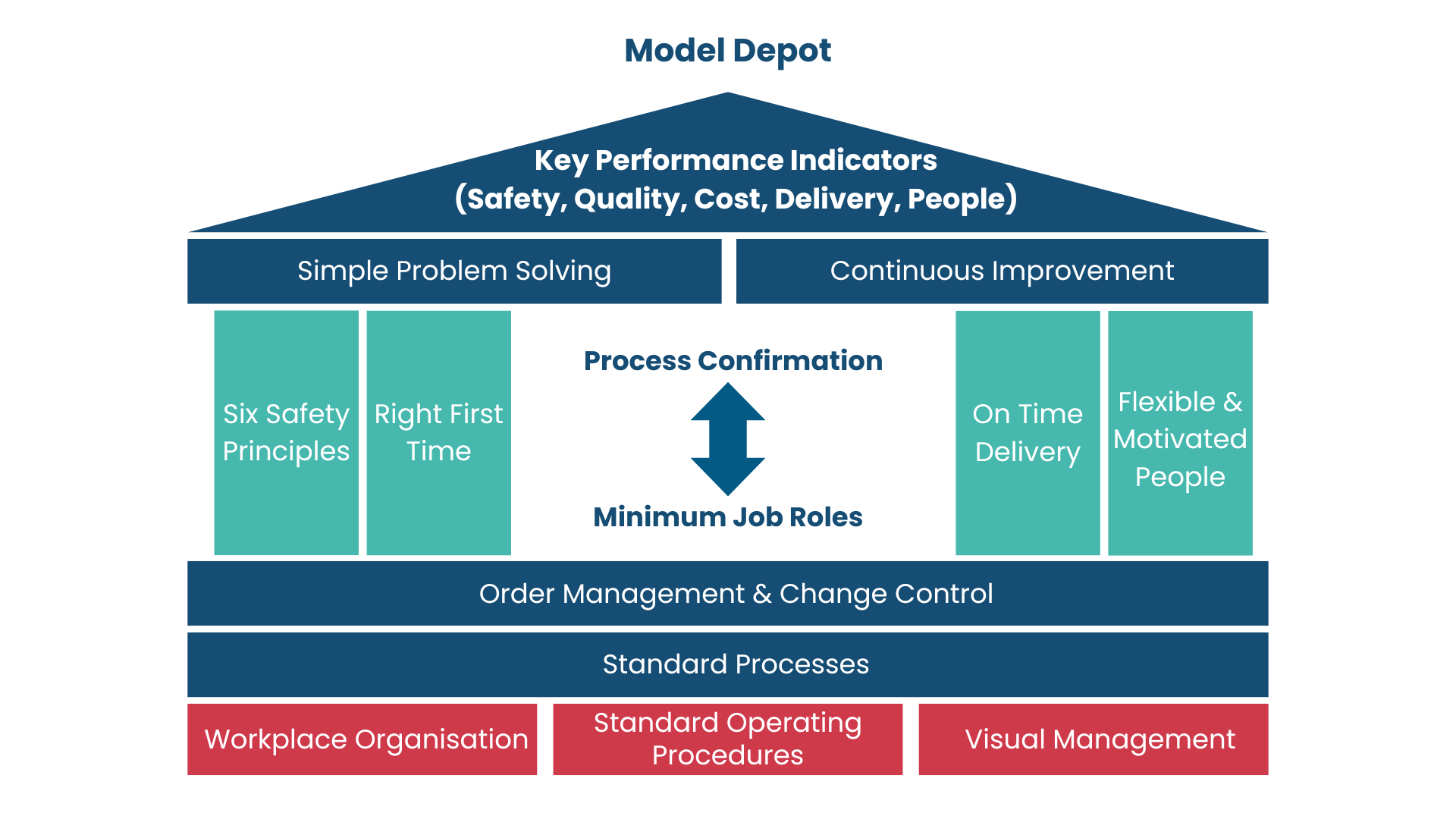

A critical component of the transformation was the introduction of a ‘model depot’ systematic approach.

This bespoke framework provided simple, visual control tools, processes and standards to enhance business performance tracking, problem resolution, and the overall working environment. Model Depot standards were developed to ensure that performance improvements at depot level were sustained for the long-term.

New ways of working included:

-

Increased visibility and management over daily and weekly performance and operations, including scheduling, route optimisation, and delivery control.

-

Enhanced pre-kitting processes and pre-delivery processes to minimise reworks and failures.

-

Standardised procedures for delivering greater process efficiencies and repeatability.

-

Introduction of leader and team role checklists with regular process confirmation by leadership teams to reinforce consistency and drive continuous improvement.

Key to the success of this phase was close collaboration with on-site teams. This involved engaging with depot and delivery managers from the offset to fully embrace new tools, processes and standards, whilst working across depots to understand local requirements and ensuring depot teams recognised both purpose & benefits.

Throughout the project our team worked hand-in-hand mentoring and coaching teams on how to lead and manage all new processes effectively. Our structured approach ensured we were building internal capabilities rather than simply installing new tools.

The results: A repeatable high-performance model delivering tangible outcomes

The Model Depot systematic approach significantly improved the operational effectiveness of the business in a number of ways:

Greater visibility and control over daily operations

Increased efficiency through standardised asset management

Fully trained and engaged teams, ensuring sustained leadership and performance management

This has resulted in significant outcomes for the business overall, including measured increases in efficiency, productivity and profitability, with a forecasted return to targeted operating profits by year end.

Most importantly, the depot has become a catalyst for high performance, empowering people to proactively drive continuous improvement.

Get in touch to understand how our approach can help you to transform your business.